Self-Healing Concrete

Concrete is prone to cracking as water evaporates leaving behind large voids. Infiltration of aggressive agents through the cracks corrodes steel reinforcements, which leads to concrete failure. Concrete with self-healing properties blocks the pathways for such aggressive agents through different mechanisms. It works by hydrating un-activated cement in the concrete matrix, filling cracks through capillary motion, formation of certain hydroxide and calcium carbonates, and extension of the hydrated cement matrix. As cracks break the healing agent microcapsules, they release the healing agent, triggering polymerization, which closes the cracks. The addition of appropriate dosages of carbonates and expansive agents contributes to the increased recrystallization of cementitious and precipitated particles, improving self-healing capabilities.

As bacteria on crack surfaces become activated by water penetrating the concrete, they multiply causing the precipitation of calcite, which fills the cracks and protects the reinforcements from damages caused by the external agents. Micro-crack healing can exceed 80% after being subjected to 28 wet/dry cycles, which consist in the submersion of the concrete in water until saturation, and air-drying to the initial moisture content of 20%.

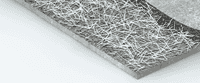

Holderchem supplies pozzolanic materials used in mix designs of self-healing concrete such as fly ash, silica fume and Ground Glass Blast Furnace Slag (GGBFS). It also supplies Polyvinyl alcohol fibers incorporated in such mix designs, and which are typically available in densities of 1300 kg/m3 and 8mm lengths.