Admixtures for Ready-Mix and Site-Mix Concrete

Mass Concrete with Reduced Heat of Hydration

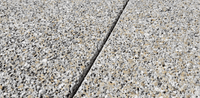

High Permeability Pervious Concrete Range

Concrete Repair and Protection

Architectural Concrete Form Liners and Molds

Epoxy-based Compounds used with Concrete

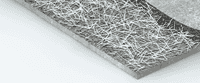

Polypropylene Fiber Concrete

Batimix Range of Products for the Pre-Cast Industry

Silica Fume for High Performance Concrete

Admixtures for Concrete Blocks, Pavers, Pipes and Roofing Tiles

Admixtures for Reducing Alkali Silica Reactivity

Roller Compacted Concrete

Admixtures for Self-Consolidating Concrete

Concrete, Mortars and Specialty Chemicals for Shotcrete Applications

Structural Lightweight Concrete

Stamped Concrete

Ready-mixed concrete is batched in a central batching plant as opposed to site-mixed concrete, which is mixed on the job site. It is delivered to contractors in a plastic condition, in-transit mixer trucks.

There are three main categories of ready mixed concrete:

- Truck-mixed concrete, which is batched at a central plant and mixed in the truck in transit. It keeps the water separate from the cement and aggregates and allows the concrete to be mixed immediately before placement at the construction site, thus avoiding premature hardening and slump loss issues that often result from transportation or placement. It is recommended for concrete that is to be delivered to construction sites located far away from the batching plant. As the transit-mixed concrete capacity is smaller than that of the same truck containing concrete mixed at the batching plant, transport costs are higher.

- Shrink-mixed concrete, which is partially mixed at the plant to reduce the volume of the concrete mix. Mixing is completed in transit or at the job site.

- Centrally batched concrete, which is produced at the ready mix batching plant to the specified job requirements.

Ready-mixed concrete is delivered ready to use. It is less time-consuming to place than a site mix. It can be delivered to different locations on site. It doesn’t require additional fixed site equipment to produce or place or storage capacity for the raw materials. It minimizes waste at the job site. More importantly, it ensures concrete with consistent quality is produced as a result of the well-controlled environment and skilled labor. Higher quality over-site concrete is achieved from lesser variations between batches. It is particularly suitable for large projects where high volumes are required as opposed to site mixing, which is a better option for renovation or small projects.

Transportation requirement is important in determining whether to go for ready mix or site concrete. In addition, the production of ready mix concrete in a central batching plant streamlines the preparation and production process allowing for durability, strength, and workability requirements to be achieved in a reliable and efficient manner. Because each ingredient in the mix has distinctive properties, the process of improving concrete mix design properties is challenging. All components must be tested to achieve the desired physical properties consistently.

Readymix producers can offer concrete with specified properties compliant with EN 206/CN standard, for which the desired characteristics are precisely defined. This concrete must comply with the standard and is defined by a nomenclature that depends on the following 6 criteria:

- Exposure Classes: XC; XF; XS; XD; XA…

- Strength Classes: C25/30; C30/37; C35/45…

- Consistency Classes: S1; S2; S3; S4; S5; SF1; SF2…

- Chloride Classes: cl1; cl0.4…

- Maximum Aggregate Size: D22.4; D16; D6.3…

- Types of Cement: CEMI; CEMII / 52.5; 42.5 / PM; SR-PM (PMES)

Advantages of BPS Concrete

- Guaranteed compliance with requirements and standards.

- Ability to safely incorporate an admixture that modifies the concrete properties, such as accelerator, retarder, water-reducing plasticizer, superplasticizer…

- Regular checks on the constituents.

- Fresh and hardened state analyses.

- Production in concrete plants, with monitoring and control.

- Delivered in mixer trucks with options for chute discharge, conveyor belts, or concrete pumps.

Alternatively, readymix producer can supply concrete with specified components compliant with the EN 206/CN standard, for which the composition and constituents to be used are specified to the producer by the specifier, such as:

- The type and strength class of cement,

- The water-to-cement ratio (E/C) or consistency (S1, S2, S3…),

- The maximum aggregate size, their types, categories, and maximum chloride content.

This type of request is reserved for experienced specifier clients. The specifier is responsible for ensuring that their specifications comply with the requirements of EN 206 standard and that the prescribed concrete composition is capable of achieving the expected performance based on the exposure classes it will be subjected to.

The producer is responsible for providing concrete that adheres to the specified composition. Advantages of Concrete with prescribed components:

- Assurance of a product meeting the requirements of a construction site.

- Possibility to safely incorporate an admixture that modifies the concrete’s properties: setting and hardening accelerator, setting retarder, water-reducing plasticizer, superplasticizer…

- Regular checks on the constituents.

- Analyses in the fresh and hardened states.

- Production in concrete plants, with monitoring and control.

- Delivered in mixer trucks with options for chute discharge, conveyor belts, or concrete pumps.

Holderchem has leveraged its know-how and vast experience and developed a wide range of concrete products and solutions, offering site mix and central batching plant producers with a range of products that allow them to meet the most stringent demands. Its technical team supports concrete producers to achieve optimized concrete mix designs, yielding early and late superior compressive strength and concrete slump results. The range of concrete products developed includes the following:

- Precast

- Structural lightweight

- Self-consolidating

- High-performance concrete with silica fume

- Mass concrete with reduced heat of hydration

- Roller compacted

- Pervious concrete

- Polypropylene fiber concrete

- Stamped concrete

- Architectural concrete

- Shrinkage reduced concrete

- High slump concrete

- Underwater concrete