Hydraulic Binders for Masonry Applications

Holderchem supplies a range of Batimix hydraulic binders for masonry works such as block fixing, key coating, plastering, and rendering. The binders are manufactured with either white or gray cement, finely ground pozzolanic fillers, and chemical additives, proportioned at the plant under controlled conditions to assure uniformity of performance. The products also include pigments to match selected colors.

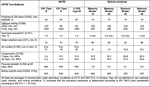

Batimix Masonry Binders are produced to meet the current requirements of EN 413-1 and ASTM C91 for Masonry Cement and ASTM C1328 for Plastic (Stucco) Cement. Their physical properties are listed in Table 1 attached hereinbelow.

At the job-site, Batimix Masonry Binders are mixed with sand and water in the right proportions to obtain mortars specifically suited for the various masonry works. Compared to mortars prepared with ordinary Type I Portland cement, the Batimix Masonry Binders offer major advantages including:

- Increased workability; The presence of fillers, air entertainers, and plasticizing agents give mortars the consistency desired for placement, enhancing workability. Masonry cement mortars cling easily to masonry units. They don’t separate on the board or trowel nor lose the excess water to the masonry units.

- Improved water retention prevents the mortar from rapidly losing its mixing water, especially when the mortar comes into contact with masonry units.

- Lower volume changes, particularly with regard to drying shrinkage and sulfate expansion. Mortars made with masonry cement have low moduli of elasticity, exhibiting the desired extensibility to accommodate expanding (clay, brick) or shrinking (concrete block) masonry.

- Better weather resistance. Rain, snow, and cold temperatures easily affect masonry ledges and sills. Instead of running off the masonry, water penetrates the vertical mortar joints. Air- entrained mortars help protect these critical areas from freeze-thaw damages. The air bubbles in air-entrained mortars give water that penetrates the mortar a place to expand when it freezes, thus reducing spalling of the mortar and masonry units caused by freezing water.

- Improved resistance against efflorescence. Masonry materials contain water-soluble salts. Walls built with masonry cement mortars do not display more efflorescence than walls built with other kinds of mortar.

- Better adhesion. The bonding strength is an important property of a mortar, as it determines the ability of a mortar to bond to the masonry units. It affects water permeance and flexural strength. Air-entrained mortars, cured in a way that resembles actual field conditions, attain higher bond strengths.

- Masonry binders have a good sand-carrying capacity. Because they contain fine-grained cement together with a set of specialty chemicals, they can carry more than the maximum amount of sand allowed in masonry mortar specifications. However, this practice is not recommended. More sand than is normally recommended (2 1⁄4 to 3 1⁄2 times the masonry cement volume) will reduce the cost of the mortar, but will also reduce its performance.

- Increased coverage ratios, mainly due to the products’ lower densities relative to Portland cement.

For assemblage of masonry units and block fixing, one part of Batimix Masonry Binder 10 is mixed with 2.25 to 3 parts, by volume, of sand to obtain a mortar as per EN 998-2 M10 or ASTM C270 Type N. All used sand shall be well graded meeting the requirements of ASTM C144 (or similar) - Standard Specification for Aggregate for Masonry Mortar. The water should be clean and just enough to obtain a workable consistency. Similar proportions are recommended when mixing Batimix Masonry Binder 20 used to obtain higher strength mortars meeting the requirements of EN 998-2 M15 or ASTM C270 Type S.

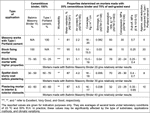

For spatter-dash slurry coat and plastering applications, it is recommended to mix one part of Batimix Masonry Binder 30 or Batimix Masonry Binder 40 with 2 to 3 parts, by volume, of well-graded natural and/or crushed sand depending on the type of element and desired strength. Alternatively, Batimix Masonry Binders 10 or 20 can be used for such applications, provided some Portland cement is added to the mortar mix. For designing the most appropriate cementitious combinations, users should refer to the “Application Guidelines” of each product or consult a Holderchem technical representative (see Table 2 for indications purposes).

Table 2 attached hereinbelow describes the typical properties of mortars made with Portland cement vs. Batimix Masonry Binders. It highlights the key advantages of using Batimix Masonry Binders as opposed to Portland cement, which can be summarized as follows:

- Reduction in the overall cost of the cementitious binder and better workability

- Higher water retention, enabling a constant rate of hardening

- Greater air content for the easier spread of mortar and better resistance against freeze-thaw

- Increased coverage ratios per m²

- Lower shrinkage and therefore, enhanced durability and quality of the finished product

- Increase permeability and a lower degree of water absorption

- Relatively similar compressive and pull-off strengths at 28 days

Batimix masonry binders are not ordinary Portland cement and should not be used to produce concrete. Holderchem cannot be held responsible for any consequential or incidental damage arising from the improper use of these products.

Batimix Masonry Binders are delivered in bulk or bags of 25kg. They should be stored in a closed dry place, and their shelf lives are six months from the production date. For health and safety directions, refer to the corresponding MSDS.

References:

- EN 413-1: Masonry cement, Part 1: Composition, specifications and conformity criteria

- EN 998-1: Specification for mortar for masonry, Part 1: Rendering and plastering mortar

- EN 998-2: Specification for mortar for masonry, Part 2: Masonry mortar

- ASTM C91: Standard specification for masonry cement

- ASTM C270: Standard specification for mortar for unit masonry

- ASTM C1328: Standard specification for plastic (stucco) cement

Statement of Responsibility: The information and application advice contained in this document are based on the present state of scientific and practical knowledge of Holderchem SAL. It is provided with no warranty, implied or otherwise, as to its completeness or accuracy. Since methods and conditions of application and use are beyond the control of Holderchem, HOLDERCHEM MAKES NO WARRANTIES, IMPLIED OR OTHERWISE, AS TO THE MERCHANTABILITY OR FITNESS FOR ORDINARY OR PARTICULAR PURPOSES OF ITS PRODUCTS AND EXCLUDES THE SAME. Holderchem warrants that its products shall be of sound materials and workmanship. As products are applied, handled and stored in manners and site conditions over which Holderchem has no control, Holderchem's liability in respect of any material which can be proven defective shall be limited to the replacement of such defective material or reimbursement of its cost at Holderchem's option. Holderchem shall not be liable for any consequential or incidental damage or loss arising out of the use of its products. Important Note: Holderchem shall have the right to modify product specification sheets at any time without previous notice. Buyers should always refer to the most recent data sheets, copies of which can be supplied upon request. The sale of products mentioned in this literature shall be subject to Holderchem's General Conditions of Sale Delivery and Payment.